Technology

How we make oatmeal Nemoloko

RAW MATERIALS PREPARATION

Our product is made from 100% Russian raw materials-environmentally friendly oats grown in the regions of the Volga and the South of Russia.

The oat area is selected, the soil is analyzed, the seeds are selected, and the crop is sown (1).

The harvest is carried out, the oats are placed in the elevator in compliance with special storage conditions (2).

Oat grains are processed into oat flour (3) in accordance with the requirements for baby food production.

THE PRODUCT OAT BASE PREPARATION

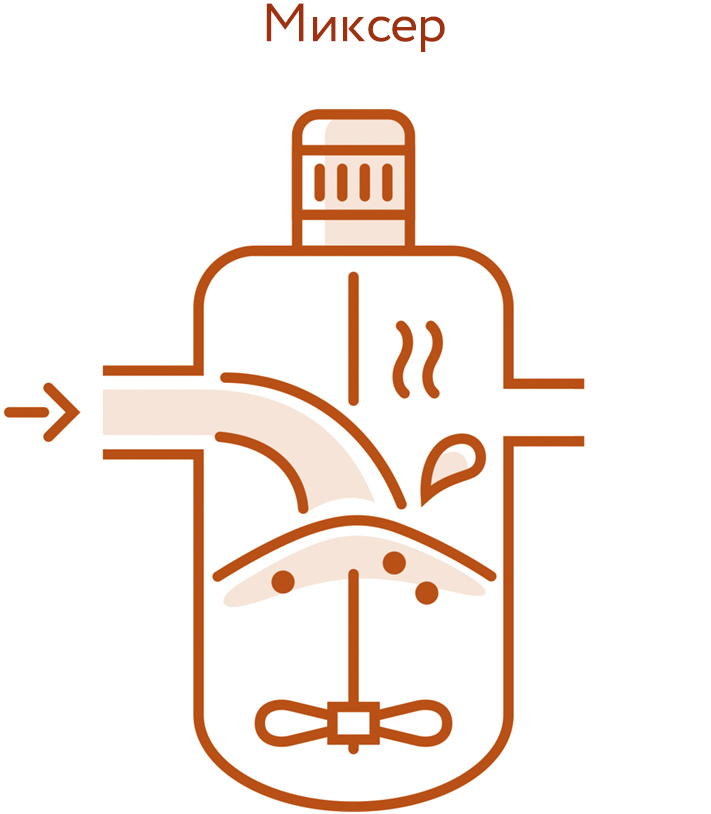

In a vacuum mixer, oat flour is mixed with hot specially prepared (purified) water, as a result of which the flour is steamed(4).

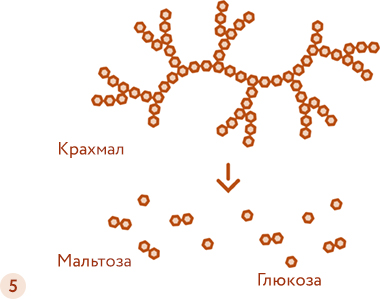

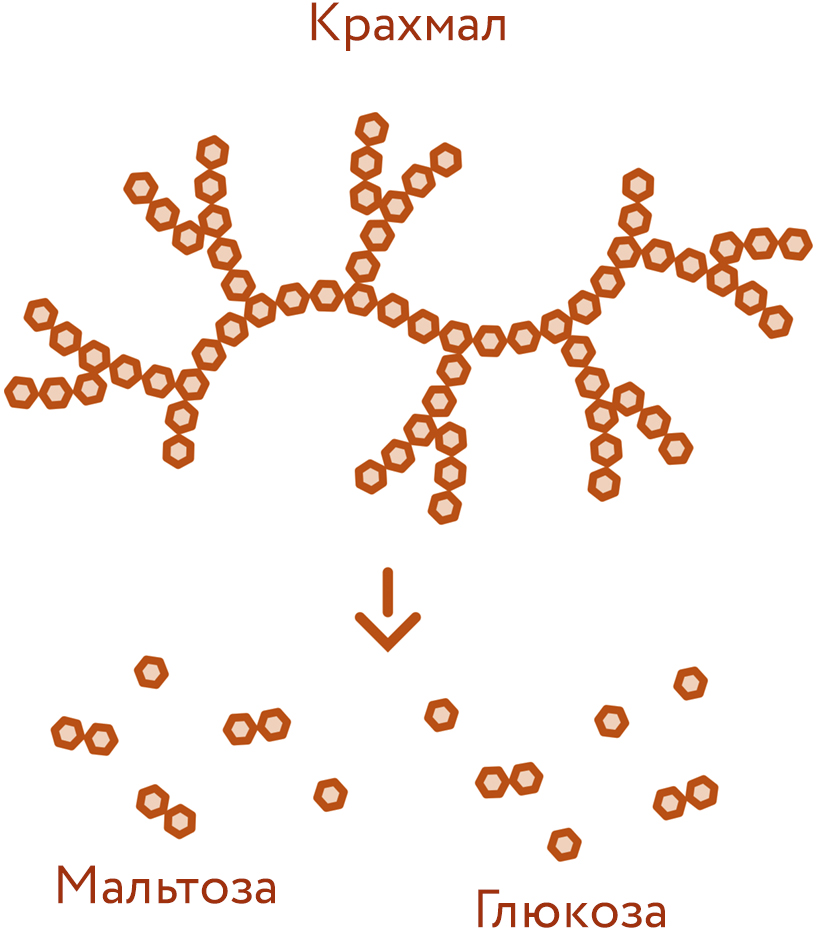

To get a homogeneous drink, oat starch must be divided into fractions that are well soluble in water. To do this, natural enzymes are added to the oat mixture. Under the action of enzymes, oat starch is broken down and partially converted into simple sugars-maltose and glucose (5). This gives a natural sweet taste to the product, which has no added sugar. The fermentation process is a key stage in the product preparation, that is why it is impossible to get an oat drink of this quality at home.

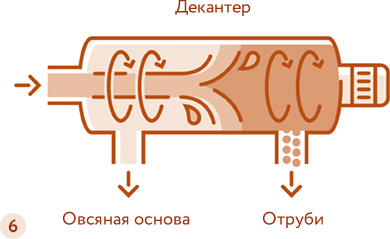

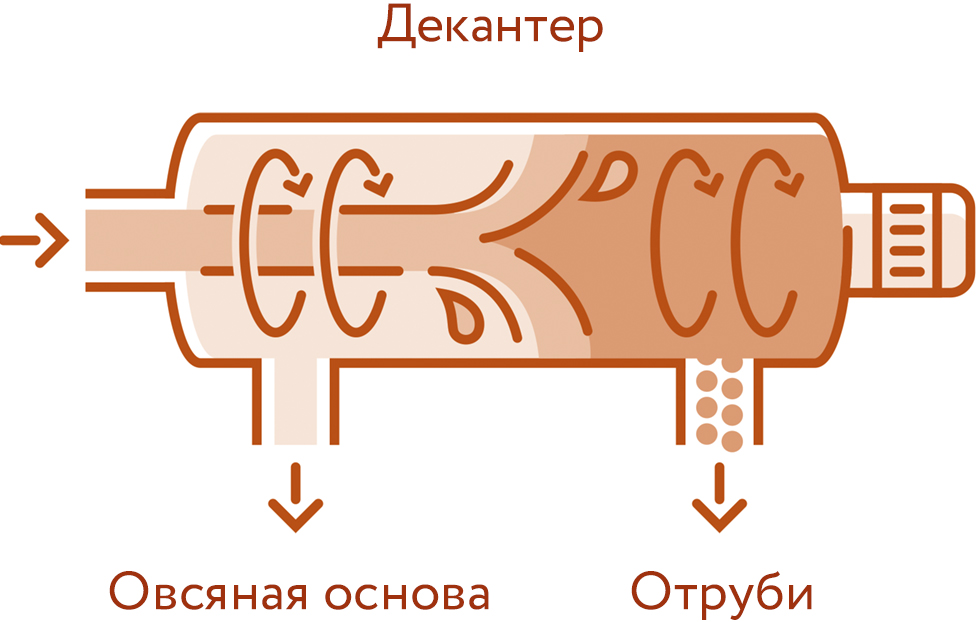

After fermentation, the enzymes are deactivated. The processed oatmeal mixture is fed to decanter (separator), where the solid fractions of oat flower are separated, resulting in a homogeneous drinking product – oat base (6).

PREPARATION OF FINISHED PRODUCTS

Various ingredients are added to the oat base in accordance with approved recipes (7). These can be trace elements and vitamins for enriching products, fruit additives (juice or puree), cocoa powder, vanilla extract, a small amount of salt, and others. To achieve the desired fat content, vegetable (rapeseed, eruk-free) oil of the highest quality is used.

The finished product undergoes a gentle heat treatment - ultra-pasteurization (8). Short-term heating and rapid cooling allow it to ensure its microbiological purity and preserve useful substances, vitamins and trace elements as much as possible.

The product is filled in a 1.0 l or 200 ml Tetra Pak package (9).

Ultra-pasteurization and aseptic filling (it takes place in a completely closed sterile space, with no air access), allow you to store the finished product at room temperature for a year. There are no preservatives in the product!

STORAGE AND TRANSPORTATION

All finished products (Tetra Pak packges) are packed in cardboard corrugated boxes of 12 pieces, formed into pallets and wrapped with stretch film. This is done to better preserve the package image and prevent possible damage during storage and transportation.

The product is stored at a constant temperature from 0 to 25 degrees in dry, clean rooms in a modern, equipped warehouse of the manufacturer and its dealers (10).

The products shelf life is 12 months, subject to storage conditions.

The products are transported by road (or railway) in compliance with the storage temperature regime (11).

Store in the refrigerator after opening for no more than three days (12).